ADVERTISEMENT

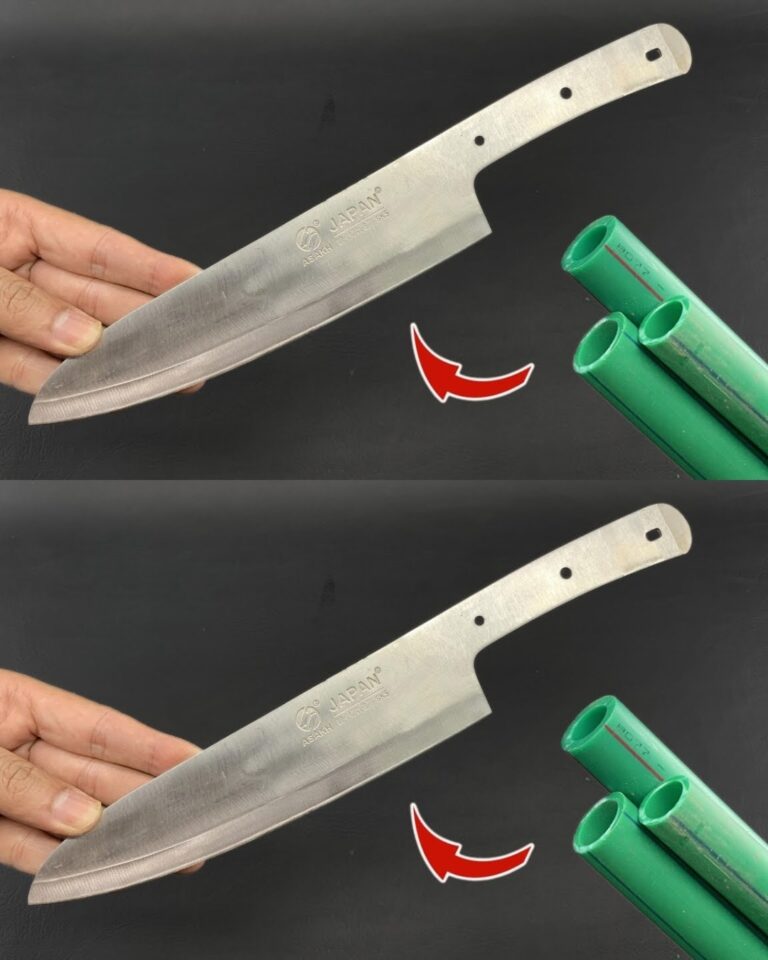

Step-by-Step Instructions to Create a PVC Knife Handle

Prepare the PVC Pipe

Cut the PVC pipe to a length slightly longer than the desired handle length. This allows for adjustments and ensures you have enough material to work with.

Heat the PVC

Use a heat gun to evenly heat the PVC pipe until it becomes pliable. Be sure to apply the heat gradually to avoid melting or burning the pipe. The goal is to soften it enough to mold around the knife base.

Mold the Handle

Once the PVC is heated and pliable, carefully mold it around the base of the knife. Ensure it fits snugly, and allow it to cool slightly while you shape it. You can adjust the positioning of the pipe to make sure it stays in place.

Cool and Set the Shape

Use cold water to cool the PVC quickly. This will help it set in the desired shape and solidify into a sturdy handle.

Finish the Handle

Once the PVC is cool and firm, sand the surface to smooth out any rough edges. This will improve both the grip and the appearance of the handle. You can use sandpaper with varying grits to achieve a finer finish.

Additional Tips for Perfecting Your Handle:

ADVERTISEMENT